Clinker grinding is the stage in which... Great Wall ...

Clinker grinding is the stage in which the final product stage in cement production,it is independent of each other. In this stage, the cement clinker...

WhatsApp)

WhatsApp)

Clinker grinding is the stage in which the final product stage in cement production,it is independent of each other. In this stage, the cement clinker...

Dec 20, 2016· There are six grinding systems available for the grinding of clinker . Conventional closed circuit system consisting of ball mill, bucket elevator and high efficiency separator. Pre grinding with a roller press and subsequent finish grinding in a ball mill operating in either open or close circuit.

Dec 18, 2016· Clinker after cooling in the clinker cooler, is transported by metallic conveyors and stored either in open or covered areas for aging which improves the grinding efficiency in the subsequent operation in the cement mills and increases the mill output rate. The aging of clinker is commonly done for a period not less than 20 days.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

clinker grinding unit project report . Cement production is a large energy consumption. Raw materials, coal and clinker grinding process are three power consumption accounts for about 70% 72% of the total power consumption of the cement plant, so the key to reducing the power consumption of cement production is to reduce the clinker grinding unit power consumption.

The clinker grinding unit for ash is a threedimensional structure with a small footprint and systemization, from roughing to final conveying to milling and packaging. It is an independent production system. 2. After the clinker grinding device is subjected to ash treatment, the fine powder has uniform fineness and the sieving rate reaches 99% ...

Grinding systems are either ''open circuit'' or ''closed circuit.'' In an open circuit system, the feed rate of incoming clinker is adjusted to achieve the desired fineness of the product. In a closed circuit system, coarse particles are separated from the finer product and returned for further grinding.

Clinker Grinding Unit The production capacity Of the Clinker Grinding Unit Will be Million TPA Cement (opc The steps involved in the manufacturing process are as follows: Clinker handling Fly Ash Handling Gypsum storage handling Cement Production Coal and pet qke handling and hot air generator Cement packing and Dispatch

May 20, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %.

Air Separation System manufacturers Sama Engineering Works exporters suppliers of Clinker Grinding Unit, Air Separation System, Rotary Kiln manufacturer, wholesale Clinker Grinding Unit .

¤ Clinker Grinding Unit. Ask for Price Ask for Price Ask for Price. We are the leading manufacturers of Clinker Grinding Unit in India. Product Details : Technology : Open Circuit and Close Circuit System: Application: Grey Cement for OPC, PPC and Slag Cement, White Cement: Capacity:

Clinker grinding technology is the most energyintensive process in cement manufacturing. Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy consumed and account for most of the manufacturing cost.

Cement Grinding Unit For Cement Manufacturing Grinding Plant Cement Grinding Unit features big crushing ratio, reliable operation, easy ... into the mill, grinding system can improve the yield and reduce power consumption. ...

Cement grinding shall be carried out in closed cement mill. Further, provision of dust extraction and pollution control system consisting of highly efficient Bag Filters and ID Fan should be provided for Cement Mill, Clinker Silo, Fly Ash Storage Silo, Cement Silo, Wagon and Gypsum Crushing Plant with adequate stack height.

Nov 25, 2015· Watch in our app . Open in app

cement high pressure clinker crusher Machine. Highpressure roller grinder of cement clinker and hard brittle clinker grinding unit italy in Algeria Gold Ore Crusher The MTM130X machine can be used for grinding various kinds of nonflammable and nonexplosive minerals of which Moh''s hardness is less than .

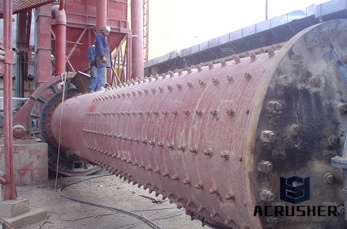

Clinker Grinding Unit Great Wall. Clinker Grinding Unit has powder separator, adopts hot air transport materials, the powder and gas enter into powder separator when out of mill. Therefore, Clinker Grinding Unit system has simple technology, low failure rate, high operation efficiency, compact allocation, construction area of 70% of ball mill ...

• Complete ancillary system of water, power pneumatic system. Different sections/components of the above processing units are tabulated as below: Processing Unit Processing Unit comprises Of 1 Clinker unloading, handling, Storing and retrieval system Wagon tipplers, Belt Conveyor, Clinker Silo, Belt Conveyor, drives, instrumentation.

Therefore, Clinker Grinding Unit system has simple technology, low failure rate, high operation efficiency, compact allocation, construction area of 70% of ball mill, construction space of 5060% of ball mill, and it can help enterprises to save land resources effectively. 3. With excellent environmental benefit, low noise, and low dust. 4.

Laxmi Engineers Cement plant manufacturer, cement machinery india, cement plant supplier, cement machinery manufacturer, cement plant and machinery, manufacturers of mini cement plant, cement machinery suppliers, mini cement plant machinery, cement plant and machinery, mini cement plants, cement machinery exporters, mini cement plant suppliers, cement plant india, wholesale cement .

We are offering quality Clinker Grinding Unit Construction Service. We have appointed a technically proficient team that includes experienced engineers, technicians and other proactive employees, who hold versatile knowledge of the domain.

Clinker grinding aids. Gypsum is added to clinker primarily as an additive preventing the flash settings of the cement, but it is also very effective to facilitate the grinding of clinker by preventing agglomeration and coating of the powder at the surface of balls and mill wall.

Cement clinker grinding unit vertical mill adopts reasonable and reliable structural design, with advanced technological process, set drying, grinding, separator, upgrade in one, especially in the large grinding process, fully meet customer demand, the main technical, economic indicators have reached the international advanced level.

WhatsApp)

WhatsApp)