Copper Brass Cold Rolling Mills YouTube

Sep 04, 2018· Copper Brass Cold Rolling Mills Dharmachand Offical Channel. Loading... Unsubscribe from Dharmachand Offical Channel? Cancel Unsubscribe. Working... Subscribe Subscribed Unsubscribe 7.

WhatsApp)

WhatsApp)

Sep 04, 2018· Copper Brass Cold Rolling Mills Dharmachand Offical Channel. Loading... Unsubscribe from Dharmachand Offical Channel? Cancel Unsubscribe. Working... Subscribe Subscribed Unsubscribe 7.

Tandem Rod Mills. The unique design of the Waterbury Farrel Tandem Rod Mill permits a series of mills to be arranged in sequence while minimizing footprint. This enables a greater reduction in a single straightthrough pass than would be possible with other coldrolling processes, all at significantly lower production costs.

on reversing mills for copperalloys. Formulated with synthetic lubricant and esters that provide rust protection and excellent lubricating properties. Fenella ® CCR Series These lubricants are designed for cold rolling mills producing nonferrous materials such as copper alloys. They are fully

Oct 31, 2014· The mechanical properties of a copper alloy can vary drastically depending on the thermalmechanical processing of the alloy during production or post production of the material. The temper designation system is used for all forms of wrought and cast copper and copper .

Cold Rolled Tempers. Cold working of copper and copper alloys, by rolling or other methods, will increase both tensile strength and yield strength in a very predictable manner. Most copper alloys are produced to a series of coldrolled tempers with a tensile strength range unique to .

The Revere Copper Company is a copper rolling mill in the United operated North America''s first copper rolling mill. It was started by Paul Revere in 1801 in Canton, Massachusetts and developed a commercially viable process for manufacturing copper sheets.

Quaker Chemical is dedicated to engineering the best cold rolling oils for your specific rolling process. From natural to synthetic lubrication. ... multiple stand mill used as a last stand cleaner in ...

Rolling processes 51 introduction: Rolling is the process of reducing the thickness or changing the cross section of a long workpiece by compressive forces applied through a set of rolls, as shown in figure (51). Fig. (51) Most rolling is carried out by hot working, called hot rolling, owing to the large amount of deformation required.

To help you meet this demand, we supply plants for the production of materials and semifinished products as well as finished products made of copper and highend alloys. Equally valuable for you is that we draw on plantspecific knowhow for the entire process chain as well as extensive expertise about the specifics of processing different alloys.

Copper tube Double Line Cold Pilger Mill LG20X2. LG20X2 double line cold pilger is used to roll two pieces of tubes at the same time. It is popular to produce copper tube with small size. Compare with single line, the output is double, it is convenient for mass producing.

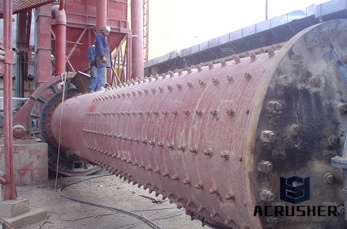

The Hot Rolling Mills for Copper Brass is specially designed for precisely rolling the sheets, rods, coils and slabs of copper brass. Our mills are developed from the topnotch quality materials and cutting edge techniques to ensure longevity and rigidity.

Brief Introduction The copper rod cold rolling mill uses two rollers to compress and elongate the raw copper into usable copper rods. Cold rolling is a highly efficient metal casting process that minimizes power consumption without sacing quality.

Rolling is done both hot and cold. It is accomplishes in rolling mills. A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc. Rollers may be plain or grooved depends upon the shape of rolled product.

Coldrolled sheets and strips come in various conditions: fullhard, halfhard, quarterhard, and skinrolled. Fullhard rolling reduces the thickness by 50%, while the others involve less of a reduction. Cold rolled steel is then annealed to induce ductility in the cold rolled steel which is simply known as a Cold Rolled and Close Annealed.

Rolling mills are not a standard machine tool, nor are they built for stock. They are designed and builttoorder to specifically accomplish an end product or process. At one point during the industrial revolution in America, the United States led the world in hot and cold rolling, plate mills, slabbing mills and blooming mills.

Sep 11, 2014· Customers often ask us about the differences between hot rolled steel and cold rolled are some fundamental differences between these two types of differences between hot rolled steel and cold rolled steel relates to the way these metals are processed at the mill, and not the product specification or grade.

Jan 23, 2014· Rolling Mill Textures On Metal Thursday, January 23, 2014 ... cinnamon jewellery etsy folksy handmade copper jewellery rolling mill silver and copper textured card texturing metal with a rolling mill using textured card in a rolling mill. Labels: ...

We are a leading innovator in metal processing equipment, which includes designing, manufacturing and servicing of coil processing equipment, rolling mill equipment, extrusion presses and copper .

The # 1 place to find new used 4 high rolling mills for sale. Buy or sell machinery equipment quickly easily

Sep 04, 2018· Copper Brass Cold Rolling Mills Dharmachand Offical Channel. Loading... Unsubscribe from Dharmachand Offical Channel? Cancel .

The Hot Rolling Mills for Copper Brass is specially designed for precisely rolling the sheets, rods, coils and slabs of copper brass. Our mills are developed from the topnotch quality materials and cutting edge techniques to ensure longevity and rigidity.

Somewhat less than half the copper input is refined and the rest is scrap. Fabricating processes, such as hot rolling, cold rolling, extrusion, and drawing are employed to convert the melted and cast feedstock into mill products.

Finishing Cold Rolling Mills for Copper and Copper Alloys Four high single stand reversing cold rolling mills for mill finishing process. Strip width up to 1200 mm. Rolling Mills can be designed as roughing/finishing or only finishing depending on the end use.

Wuxi Wuye Heavy Industry Machinery Co.,LTD is best Cold Rolling Mill, Rolling Mill Machines and Tandem Rolling Mill supplier, we has good quality products service from China.

WhatsApp)

WhatsApp)