Ball MillChina Mining Machinery

35 rows· Wide Application of Ball Mill Ball mill, as the key grinding equipment of the materials, is .

WhatsApp)

WhatsApp)

35 rows· Wide Application of Ball Mill Ball mill, as the key grinding equipment of the materials, is .

Mining Grinding Ball Mill In Copper Ore Grinding. Sag is an acronym for semiautogenous grinding sag mills are autogenous mills that also use grinding balls like a ball mill a sag mill is usually a primary or first stage grinder sag mills use a ball charge of 8 to 21 the largest sag mill is 42 128m in dia,Mining grinding ball mill in copper ore grinding.

Grinding The ore is ground into a fine powder by large rotating mills. The two types used in the Mission South Mill are called SAG (semiautogenous grinding) mills and ball mills. SAG mills use larger pieces of ore to break up the smaller pieces (autogenous — does it .

In the continuous type Ball Mill, the material is being fed from the one end through its hollow shaft, while the crushed material comes out from the hollow shaft, at the other continuous Mills are used when the production rate is required to be high. Specially designed for :Cement, Iron Ore, Copper Ore, Alumina, Cement, Calcium Carbonate, Bauxite, Calcium Carbide, Calcium Oxide ...

Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

A section of a commercial ore grinding operation is shown in figure 1. This section consists of 13 rod mills and 26 ball mills, which are on the left of the picture. Each ball mill weighs more than 150 st, processes 85 st of ore per hour containing approximately 1,000 lb of copper and consumes approximately 95 lb of grinding balls during that time.

For this study, materials (copper sulphide ore) were sampled from the SAG mill feed in Sungun copper concentrator plant. The density of ore was g/cm ore was crushed in a laboratory scale jaw crusher and roll crusher successively to prepare materials for ball mill grinding tests.

Grinding Plant 〉 Ball mill 〉 Rod Mill 〉 Intermittent ball mill 〉 Cone ball mill 〉 Cement mill 〉 Ceramic Ball mill. Drying Calcine Equipment 〉 Hot Air Furnace 〉 5HXG Low temperture circulation grain dryer 〉 LGH grain dryer 〉 HVPF vertical automatic filter press 〉 Chamber filter press 〉 Plate and Frame Filter Press

Copper Ore Ball Mill Description of Copper Ore Ball Mill According to the different beneficiation process, the equipment for copper ore dressing are different, in general, jaw crusher, impact crusher, vibrating screen, ball mill, classifier, flotation machine and dryer. Copper ore mill is the key equipment for second grinding after the copper ...

Since metallic copper is malleable, it cannot be broken and pulverized as can the more friable minerals, and after first picking out the larger lumps or nuggets of copper by hand, crushing is done by steam stamps; pebble mills instead of ball mills are employed for grinding .

offers 1,481 ball mill for grinding copper ore products. About 82% of these are mine mill, 2% are other fabrication services, and 1% are grinding equipment. A wide variety of ball mill for grinding copper ore options are available to you, such as ac motor, dc motor, and stepper motor.

Wetdry ball mills. Dry grinding: grinding the material into the desired mineral powder (usually used on the grinding of hard materials). Wet grinding: grinding the material into a certain concentration of ore pulp, generally 6070% concentration (usually used in various mineral processing). Features of ball mills. Energy saving: fully hydraulic operation, easy to use and automate, which ...

Here is a convertible laboratory ore grinding mill. Use it as a Lab Ball Mill if you like overgrinding or a Rod Mill if you prefer selective milling. Sizes 8″ x 8″ to 8″ x 16″ (ball and rod) Extra Large Batch 12" x 15" (10 kilo ore load) Mild steel construction Cantilever design Integral lifters Bayonettype lid closure Rubber seal gaskets Wash screen Motor/reducer and vbelt drive ...

China Ore Ball Mill for Grinding Copper, Gold, Manganese Ore, Find details about China Ore Ball Mill, Gold Ore Ball Mill from Ore Ball Mill for Grinding Copper, Gold, Manganese Ore Henan Zhengzhou Mining Machinery Co., Ltd.

China Copper, Gold Mining Ore Grinding Ball Mill Equipment, Find details about China Grinding Equipment, Mining Equipment from Copper, Gold Mining Ore Grinding Ball Mill Equipment Henan Yuhui Mining Machinery Co., Ltd.

Grinding The ore is ground into a fine powder by large rotating mills The two types used in the Mission South Mill are called SAG semiautogenous grinding mills and ball mills SAG mills use larger pieces of ore to break up the smaller pieces autogenous does it. View Details Send Enquiry Paper 25 Copper Mountain Overview On The

Cement Mill, Ball Mill, Grinding Ball Mill manufacturer / supplier in China, offering Ball Mill for Gold Ore, Rock, Copper, Cement Grinding, High Quality Casting Steel Lining Plate / Liners for Grinding Mills, High Quality Pinion Gear for Rotary Kiln Gear for Cement Ball Mill and so on.

Copper Ore Processing PlantParameter and Quote Fote. 2 Grinding The crushed copper ore gravel is evenly sent into the ball mill for further grinding to obtain smallersized copper ore fines to complete dissociation of the ore Then the copper ore is graded by a spiral classifier and the nonstandard ore will be returned to the ball mill for further grinding 3 Flotation The qualified copper ore ...

Oct 12 2017 sag mill make use of steel balls included with some large and hard rocks for grinding these mills utilize the balls in making the large fragments of materials broken into pieces the ball charge of a sag mill is about 9 to 20this process takes,Types of ball mills for copper ore grinding.

Ball Mill For Copper Ore In Pakistan. The process of copper ore grinding belongs to a closed circuit in which the oversized particles of copper ore are returned from the post milling process to be remilled until the size of final product achieves the requirement For those small copper investors in Pakistan ball mill performs as a popular type ...

Copper Ore Grinding Ball Mill From Iso. Copper Ore Ball Mill With Iso Certifie 250tph river stone crushing line in Chile Copper ore beneficiation plant Iron Ore Beneficiation Plant 20TPH vertical mill for limestone desulfurization in power plant 325mesh calcium carbonate production line MTW trapezium mill .

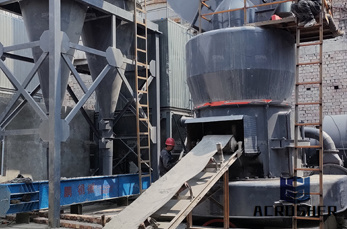

Wide Application of Ball Mill Ball mill, as the key grinding equipment of the materials, is widely used for mineral grinding such as cement, lime, quartz, slag, silica, iron ore, copper ore, gold ore, bauxite, calcite, barite, gypsum and other minerals in mining, quarry, chemical, cement and other industries.. Ball mill is the necessary equipment in ore beneficiation plant.

Research was done by the Bureau of Mines to determine the effect of a lowmolecularweight polymer on wet grinding of quartz, dolomite, and a copper ore. A 5in ball mill equipped with a torque sensor for precise measurement of input energy was used for batch grinding tests.

Ball mill is the key equipment for grinding materials. those grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, iron,zinc ore, copper, etc.

WhatsApp)

WhatsApp)