Flow Diagrame Of Dry Process Of Manufacture Of Cement

Manufacturing Of Cement By Dry And Wet Process. Sep 08 cement manufacturing process flow chart i drying zones in the wet process the drying zone is comparatively larger than dry process .

WhatsApp)

WhatsApp)

Manufacturing Of Cement By Dry And Wet Process. Sep 08 cement manufacturing process flow chart i drying zones in the wet process the drying zone is comparatively larger than dry process .

Feb 16, 2016 Cement manufacturing process components of a cement plant from quarry to kiln to cement mill. More information Cement Manufacturing Process Simplified Flow Chart

In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill. The raw materials are dried and reduced in size to a fine powder in to grinding mill. The dry powder is called the raw meal. The raw meal is pumped into a .

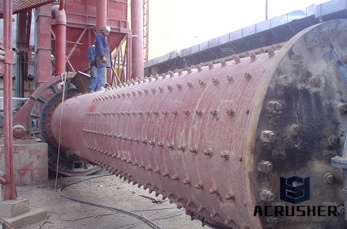

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement ki...

| The cement manufacturing process flow chart is a sample which describes the process by which cement is created. From procuring the raw materials to how they are mixed, stirred. Stored, mixed, etc is been explained.

Cement Manufacturing Process Flow Chart hotcrusher In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc Limestone is the main raw material for cement production.

May 28, 2019· Cement Manufacturing Process Flow Chart; Cement manufacturing components of a cement plant, How Cement Is Made? manufacturing o...

Methods of Manufacturing Process of Cement. At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process. The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry state.

Mar 15, 2017· Cement manufacturing process components of a cement plant from quarry to kiln to cement mill.

Cement Mill Process Flow Chart Cement mill process flow chartement production process 11,891 views share like download, deepesh mishra follow, process flow chart 6, this fine ground coal is used for burning in the kiln 14 cement mill and bag house clinker, along with additives, is ground in a cement mill the output of a cement mill is the final product viz cement .

Manufacturing of cement flow chart dry process Nowadays many cement factories used modern production technology to increase capacity and quality of cement. In modern technology, they use the equipment, such as a cross belt analyzer manufactured by GammaMetrics of USA to find the composition of limestone at the conveyor belts, highpressure ...

Cement Manufacturing Process Flow Chart hotcrusher. Cement Manufacturing Process Flow Chart; Cement manufacturing process is mainly divided into three stages, namely, raw meal preparation, clinker burning and cement grinding A preheater consists of several stages contained in a tall preheater tower, which utilizes the heat produced by the flame at the firing end from the kiln to .

FLOWCHART 1. Convert the following flow chart into a paragraph of about 150 words. The process of making cement is described in this flow chart. The two raw materials used in theprocess are .

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches.

Manufacturing Of Cement By Dry And Wet Process. Sep 08 cement manufacturing process flow chart i drying zones in the wet process the drying zone is comparatively larger than dry process in is because the raw material in slurry form is directly fed into .

Sep 17, 2015· Cement Production Process 1. By: Deepesh Kumar Mishra Satna Cement Works Birla Corp. Ltd. Six Weeks Training Report 2. Satna Cement Plant ... Process Flow Chart 6. 00. Limestone Quarry and Crushing plant The major raw material for cement production is limestone. The limestone most suitable for cement production must have some ...

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays .

Cement industry process flow chart Mining . Cement Industry Flow Chart . Cement Manufacturing Process Flow Chart Cement manufacturing process is mainly divided into three stages namely raw meal preparation clinker burning and cement grinding Generally speaking the cement industry production is Portland cement Portland cement .

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

The cement manufacturing process consist of the following multi stages as explain in the following flow chart. Flow Diagram of Cement Manufacturing Process Wet Processes Dry Processes Raw material preparation (Proportioning and Grinding) Raw material processing (Primary and Secondary Crushing) ...

Cement Manufacturing Process Flow Chart – Mining Machinery. Shanghai XSM machinery co., LTD is a large stone production line, sand production line is given priority to, set design, manufacture, sales and service as one of the international hightech heavy equipment manufacturing company, the production .

The cement manufacturing process flow chart is shown as follows: Cement Manufacturing Process. And Preblending (1)Crushing: In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs ...

Mar 15, 2017· Cement Manufacturing Process Simplified Flow Chart March 15, 2017 May 11, 2013 by Johnny Cement Manufacturing Process Cement Manufacturing Process Simplified Flow Chart

Aug 30, 2012· The remaining cement is shipped in bulk quantities by mean of trucks, rails or ships. Cement Manufacturing Process Flow Chart. After explaining the complete process of cement making, flow chart would be like that. flow chart present the summary of whole process as shown below.

WhatsApp)

WhatsApp)