BAll Mill Installation YouTube

Apr 02, 2013· Installation of a 23,000 pound Ball Mill in the Carissa Mine at South Pass City State Historic Site

WhatsApp)

WhatsApp)

Apr 02, 2013· Installation of a 23,000 pound Ball Mill in the Carissa Mine at South Pass City State Historic Site

How to Replace the Ball Mill Liner Facebook. nbsp 0183 32 Ball mill is an indispensable equipment in the beneficiation operation because it is necessary to grind the ore to a suitable particle size to extract high grade concentrate from the ore Thus choosing a suitable ball mill from the pre purchase consultation to the smooth installation of the ball mill the test run takes a lot of time and ...

The ball mill is a key equipment to grind the crushed materials Simple structure and split installation Ball mills are cylindrical in shape Ball Mill Installation Contractor Equipment udaikothiin The ball mill for the installation of horizontal method of ball mill Lime mill Ball mill grinding equipment is .

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles ...

Ball mill installation is a link that must be experienced before the ball mill is put into operation The installation will affect the subsequent use of the ball mill and even affect the production crushing rate service life and so on so the importance of ball mill installation is selfevident. Ball Mill Installation Guide Crusher Mills Cone Crusher

Mill Installation Manual 16x22ft, 2800kW Ball Mill. TABLE OF CONTENTS. Get Price; How to Improve the Production of Ball Mills? LinkedIn. Aug 9, 2017 The solution is that the operator must ensure the ventilation rate of ball mill and install the air suction device in the drawing pipes, to improve the Get Price; Ball Mill Installation DIAB ...

To Install The Ball Mill Correctly. The installation quality of the ball mill is the key to ensure the normal operation of the mill the installation methods and order of various types of ball mills are approximately the same here is the correct installation steps

Prices Quote Ball Mill Installation br Ball Mill Installation List Home › Product list › mining machine › mining machine ball ball mill installation is complete after passing test and then empty car test ball mills trial operation of ball mill by skilled operators shall be responsible for ball mill and strictly abide by rules of safe operation

p. 1 how to purchase and install a ball mill 1,to select a suitable ball mill according to their own hardness of minerals 2,selected energysaving ball mill 3 master of the fineness of mineral requirements 4 according to production requirements select the mill diameter and length 5 best professional manufacturer of your minerals relative to.

Installing Ball Mill In Router. Production capacity : /h . Feeding Size : ≤25mm . Discharging Size : Ball mill is also known as ball grinding mill. Ball mill is the key equipment for recrushing after the crushing of the materials. It is widely used in cement, Learn more 40 years of industry experience providing onestop ...

How To Install Best Ball Mill Driven System Dietitian. Mvr vertical roller mill conventional drive ready2grind modular system mps vertical roller mill mrd mre ball mill build and install ball mills which are specially adapted to grind hard and even extremely abrasive materials advantages of the ball mill adjustable grain size distribution

The installation methods and order of various types of ball mills are approximately the same. In order to ensure the smooth operation of the ball mill and reduce the harm to the building, it must be installed on the reinforced concrete foundation of times as much as its weight and it should be far away from factory building foundation 40 ...

Aug 10, 2020· Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder. Ceramic material, crystalline compounds, and even some metals can be ground up using a ball mill.

Jan 14, 2020· There are two kinds of transmission forms of ball mill, center transmission and edge transmission. The two kinds of transmission have their own advantages and disadvantages. The central transmission adopts a highspeed planetary reducer, which is safe and reliable, with a service life of up to 10 years, low maintenance cost, but large one ...

Before the installation of the ball mill base, the analysis should be in detail and check if it is up to the relative design requirements. Observing the main bearing of the ball mill on the center line or not. The contact ratio should not be over, and the feeding part should be .

MTWSeries European Tech. Grinding Mill. LUMSeries Ultra Fine Vertical Grinding Mill. Trapezium Mill. Micro Powder Mill. Raymond Mill. VM Vertical Grinding Mill. Vibrating Screen. Screw Sand Washing Machine. Wheel Sand Washing Machine. Vibrating Feeder. Belt Conveyor. TSW Series Vibrating Feeder.

Wiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and ceramics." Many instructables refer to United Nuclear Ball Mills. Their small ball mill cost between 70 and 80 dollars. For no more than 30 and in 5 minute you can build a ball mill of appreciable performance.

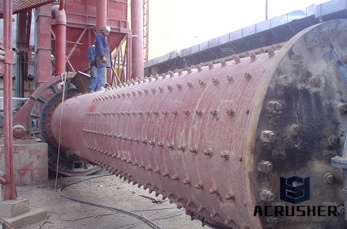

Ball Mill Installation DIAB Engineering. Ball Mill Installation. DIAB carried out the installation of this 8 megawatt iron ore grinding mill, which included assembly of all mechanicals, linings and lube...

ball mill install manual ball mill girth gear installation pdf Shanghai Labeled Photograph Description Tramming the Head Squaring the Vise Types of Milling Cutters Removing and Installing Get Price On Line » how to install a ball mill installing a ball mill pinion. article was done on a ball mill used in the power generation industry in .

Ball Mill. Ball mill is also called grinding ball mill, which is widely used for grinding raw materials or finished products in mining, cement, refractory, building materials, ore dressing, chemical industry,

This mill is going to come in really handy for lots of future projects. I hope this page gives helpful ideas to anyone in need of a ball mill. They are quick, easy, and cheap to build yourself. I need to add a disclaimer here for anyone thinking of using this sort of ball mill for milling gunpowder or other flammable or explosive powders.

Two installation points of ball mill liner. During installation, a layer (1:2) of cement mortar should be applied to the inner wall of the cylinder, and screwed before screwing. Whether it is large, medium or small ball mill equipment, it must be installed under the guidance of the technical personnel of the ball mill manufacturer.

Planetary Ball Mill Manual Three Roll Mill. planetary ball mills grind or mix solid particles of different granularities . Immediately after milling jars are filled, users can install .

The ball mill is a common mineral processing equipment. It is the quality assurance of the mineral process and related to production efficiency and product quality. The steel ball in the ball mill plays an important role in the whole production, but do you know how to add the steel ball to the ball mill?

WhatsApp)

WhatsApp)