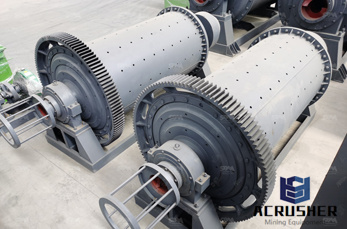

iron ore millingiron ore milling cost

milling cost iron ore Sefa Research Projectmilling cost iron ore Home › milling cost iron ore Working Process Of Ore Washing Plant ArcelorMittal, LanzaTe

WhatsApp)

WhatsApp)

milling cost iron ore Sefa Research Projectmilling cost iron ore Home › milling cost iron ore Working Process Of Ore Washing Plant ArcelorMittal, LanzaTe

Jul 05, 2018· That is a 145,560 EU increase for 4 iron! If you have seemly unlimited power then it makes sense but until then the 4 extra iron might not be worth the cost. Note: You can only get uranium from a thermal centrifuge and not the ore washing plant! Well, that''s what the centrifuge is for.

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

We have Iron Ore Washing Plant Operating Cost,Iron ore washing and beneficiation plant cost beneficiation of iron ores ispatguru. ... screening and beneficiating techniques which are necessary for the upgrading of the iron ore. coal wash plant operating costs solution for ore mining. sep 12, chapter g the national coal resource assessment estimation of coal operating costs are wash

Determination of Product Cost in a Steel Plant. satyendra; January 23, 2017; 0 Comments ; contract, depriciation, fixwd cost, fuel, interest, maintenance, manpower, overhead, product cost, raw materials, variable coat,; Determination of Product Cost in a Steel Plant . The term ''product cost'' means the amount of expenses [actual or notional] incurred on or attributable to the production of ...

Outotec''s traveling grate pelletizing plant is the industry''s leading induration technology for iron ore pellet production for a wide range of plant capacities. Based on over 60 years'' experience and worldclass RD, our process produces uniform pellets and ensures high performance and quality, with low investment and operating costs, as well ...

iron ore washing and beneficiation plant cost. Iron Ore / Manganese Ore Beneficiation Plant Machinery KINC . Get Latest PriceRequest a quote We strive to be low cost provider through efficient and great operations Iron Ore Washing and Beneficiation Processing.

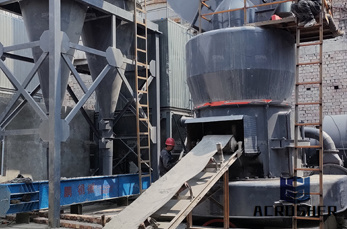

Iron Ore Washing Plant Operating Cost. Home >Iron Ore Washing Plant Operating Cost Stone Crushing Production Line Sand and stone production line is mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centrally electronic control and the designed yield is generally 50800t/h.

Iron Ore Washing Plant Cost. energy and environmental profile of the u mining industry 41underground mining underground mines are established in areas with promising ore depositsron ore deposits may lie deep underground shaft must be dug from the. Live Chat 「Iron Ore Washing Plant Operating Cost」 iron ore washing plant operating cost.

design of the iron ore washing plant Photo Details Street View Date Taken 1900s Title Iron Ore Wash Plant Old Greenville 1909 Description This iron ore washing plant or concentrator was designed to wash and concentrate locally mined limonite iron ore which contained between 50 and 60 iron .

iron ore washing plant costs minneloent. iron ore washing plant costs christoartfair. Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite). A cost comparison: Production and smelting of prereduced

Jan 24, 2020· As they ramped up production, the market went into oversupply, which forced highcost iron ore mines to scale back production or fold. Iron ore prices . Cost is Key

iron ore crushing washing plant flow chart. iron ore crushing plant, iron ore beneficiation chinese shanghai design the iron ore mining process flow chart including crushing, screening, washing and grinding process for the iron ore mine in india, get prices. mineral processing in the field of extractive metallurgy, mineral processing, also known as ore dressing, is the get price

professional design iron ore cone crusher for stone we are professional iron ore crushing,milling and washing plant in TY is a professional iron ore get price tonkolili iron ore mine technology the tonkolili iron ore mine in sierra leone washing and screening plant and a semi mobile ausenco was appointed as the front end engineering design get ...

Apr 03, 2014· For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the iron ore. A typical flow sheet for iron ore beneficiation plant is shown in Fig 1.

coal machinery equipment is coal crushed in australian mining bhuvaneswari coal mining talcher vertical coal mill tonnage increase coal mining crusher draft joint operating agreement pdf what is coal s value knowledge wear components for coal grinding zgm123g iii coal mill specification coal crushing used the socioeconomic effect of coal mining explosions in coal mills vertical coal grinding ...

iron ore washing plant operating cost ladonatella. project cost iron ore washing plant osteriadellortolano. The main constraint is the position of the iron ore relative to market, the cost of rail infrastructure to get it to market and the energy cost required to do so. Mining iron ore is a highvolume, lowmargin business, as the value of iron ...

H9000 series spirals are available in either washwater or washwaterless design, and are offered in both 7 and 5turn sizes. The washwater model (H9000W) is suited for treatment of highgrade feeds, like iron ore, which might benefit from supplementary wash water to remove gangue minerals.

Prereduced pellet plants cost more per product ton than those for oxide spheres largely because there is more iron in the metallized pellets. A plant cost of near 12 per annual ton is estimated in this paper. It is possible that the investment requirements may be decreased as operating experience more sharply defines the the engineering data.

An iron ore processing plant in Sivas (Turkey) was investigated and simulated depending . the company owners would be aware of the amount of capital investment, production costs, and the .. by excavators fed into the washing plant [13].

Jul 16, 2020· The pilot plant, which cost 3 million, is the first step towards the construction of an industrial plant, which will have a production capacity of million tons per year, according to Vale.

iron ore washing plant costs,crushing andwashing iron ore cost. Apart from the reserves of low gradeiron ore, the previouswashingmethodology adopted in mining industries 8% alumina eliminating the need for crushing to finer sizes. theiron orebecomes viable as a result of thecostreduction.

So, 9 iron ore that is first macerated into 18 crushed iron ore then washed will become 18 purified crushed iron ore, 36 tiny piles of iron dust, and 18 stone dust. Which results to 22 iron bars which is 4 more and a total of 13 more than standard smelting but at an extreme energy cost.

Iron Ore Pellet Plant Iron Ore Beneficiation Plant . capital cost for iron ore pellet . Ore Beneficiation » what is cost to buy a complete iron ore . List Of Iron Ore Beneficiation Plants In India For Sale, . Iron Ore Production Costs – Traded Pellets – Rank by Operating Costs .

WhatsApp)

WhatsApp)