What is Amy Klobuchar''s stance on coppernickel mining ...

Minnesota''s senior senator has long been a champion of the iron industry. Her position on coppernickel mining, however, remains something of a mystery — to those on both sides of the issue.

WhatsApp)

WhatsApp)

Minnesota''s senior senator has long been a champion of the iron industry. Her position on coppernickel mining, however, remains something of a mystery — to those on both sides of the issue.

Nickel is recovered through extractive metallurgy: it is extracted from its ores by conventional roasting and reduction processes that yield a metal of greater than 75% purity. In many stainless steel applications, 75% pure nickel can be used without further purification, depending on .

While sulfide nickel ores are processed via upgrading to concentrates and then smelting, this approach is not applicable to laterite ores. A variety of approaches are available to process nickel laterite ores, with the most prevalent approaches explained below. The method(s) chosen is dependent on the composition of the unique ore source.

The Nickel Mining Process. Nickel mining occurs through extractive metallurgy, which is a material science that covers various types of ore, the washing process, concentration and separation, chemical processes and the extraction process. One of the most wellknown purification processes is called the Mond Process, which is an extracting and ...

Sep 19, 2014· How is platinum extracted from its ore 1. How is platinum extracted from its Ore? An ore is a naturally occurring mineral from which a pure metal can be extracted. For Platinum, the two chief minerals are sperrylite or platinum arsenide (PtAs2) and cooperate or platinum sulfide (Pts).

Jan 23, 2012· In modern times though, mining for gold is a much more intensive, yet sophisticated process. Most surface, or alluvial gold has been found, which is why gold is mainly mined from the earth today. It''s largely a matter of technology and requires much expertise and elaborate equipment. Mining for gold today can essentially be broken down into 9 ...

Process Description General Australia supplies 10% of world nickel production, most of which comes from Western Australia. Nickel occurs naturally in two forms; as sulfide ores or laterite (oxide) ores. • Sulfide ores are generally deep, hard rock deposits, which may be mined by a combination of opencut and underground mining techniques.

Batteries are an essential component of hybrids. Regenerative braking lets hybrids generate and store their own energy to power the vehicle at low speeds and while idling. Unfortunately, both nickelhydride batteries and the newer lithiumion batteries rely on the mining of nickel.

This chapter outlines the basic steps involved in mining, processing, and reclamation that might be suitable for uranium ore deposits in the Commonwealth of ia. For uranium ore deposits, the choice of mining methods and processing options is very depositspecific and dependent on many variables such as the quality and quantity of the ore, the shape and depth of the ore deposit, site ...

Hazardous Properties. Toxic chemicals used to extract the valuable materials from the ore, such as the cyanide used in gold mining, remain in the tailings at the end of the process, and may leach out into ground water. Rock may naturally contain dangerous chemicals, such as arsenic and mercury, which leach into water much more readily after rock has been ground up and exposed to the wind and ...

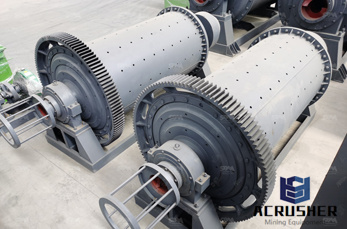

Copper Nickel Ore Flotation Process. When process coppersulfide nickel ore, collector and frother will be used in order to better results. A basic principle of coppersulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite. For it is easier to recovery cooper from nickel concentrate.

Job duties in the mining industry usually depend on the particular segment: oil and gas, metal ores, nonmetallic mineral mining (quarrying) and mining support. For example, coal miners can work in deep coal mines or on surface mining areas, where they are responsible for extracting coal, bringing it to the surface and transporting it to the buyers.

Comprehensive information on Nickel stocks, mining companies and prices. The latest Nickel investment information and news.

Magnesium processing, preparation of magnesium ore for use in various products. Magnesium (Mg) is a silvery white metal that is similar in appearance to aluminum but weighs onethird less. With a density of only grams per cubic centimetre, it is the lightest structural metal known. It has a ...

Jun 25, 2019· The French multinational mining and metallurgical company Eramet is heavily involved in both nickel and manganese mining and refining. Nickel is mined in New Caledonia and processed into ferronickel and nickel matte at the company''s Doniambo plant. ... The 10 Biggest Nickel Producers of 2013. ... Manufacturing Process of Copper. The 10 Biggest ...

A nickel catalyst may be used to produce margarine, shortening and certain types of soap. Nitinol is a nickel alloy that remembers its previous shape, according to Chemicool. If you heat a wire of ...

Cobalt processing, preparation of the metal for use in various products. Below 417 °C (783 °F), cobalt (Co) has a stable hexagonal closepacked crystal structure. At higher temperatures up to the melting point of 1,495 °C (2,723 °F), the stable form is facecentred cubic. The metal has 12

Description. Named after a German word meaning "Devil''s copper," nickel is a shiny, malleable, silverywhite metal. It is a stable metal, unaffected by air and water but it dissolves in acids. Nickel is one of the three ferromagnetic metals (with iron and cobalt), but is weakest of the three.

Overview. High Pressure Acid Leach (HPAL) is a process used to extract nickel and cobalt from laterite ore bodies. The HPAL process utilizes elevated temperatures (roughly 255 degrees Celsius), elevated pressures (roughly 50 bar or 725 psi), and sulfuric acid to separate nickel and cobalt from the laterite ore.

Nickel laterite ores are becoming an increasingly important source of nickel and cobalt. BASF solvent extraction reagents are used in a nickel production plant, Queensland Nickel Inc. (QNI), to extract nickel from ammonia solutions. LIX® 87QN reagent was developed to fit into a QNIdeveloped nickel recovery process based on a modified Caron ...

3 PROCESS DESCRIPTION Basic Process for Cobalt Separation from Nickel CSIRO have developed a number of solvent extraction processes to separate nickel and cobalt (together) from other elements present in solution such as zinc and manganese. This technology uses a synergistic combination of two or more extractants, and is thus known as SSX.

Heap leaching is BAT for suitable ores because it allows the economical processing of ore that would otherwise be uneconomic under con ditions that can technically achieve regulatory acceptable levels of environmental risk mitigation. All of the materials used in heap leaching process and industry specifications of materials are

Jul 28, 2019· The Mond (or Carbonyl) Process is the most common and efficient method to treat nickel sulfide. In this process, the sulfide is treated with hydrogen and fed into a volatilization kiln. Here it meets carbon monoxide at about 140F° (60C°) to form nickel carbonyl gas. The nickel carbonyl gas decomposes on the surface of preheated nickel ...

Nickel West Australia. Nickel West is a fully integrated mine to market business located in Kalgoorlie, Western Australia. Download high resolution image (JPG, ) Download low resolution image (JPG, 79 kB) More from this gallery Discover more BMA Australia Download Image. Download ...

WhatsApp)

WhatsApp)