Mill Feed Chute DEM YouTube

Nov 16, 2016· A discrete element model of a mill feed chute. Software used EDEM, done by Greentechnical Bulk Solids Material Flow Specialists.

WhatsApp)

WhatsApp)

Nov 16, 2016· A discrete element model of a mill feed chute. Software used EDEM, done by Greentechnical Bulk Solids Material Flow Specialists.

Feedlot Construction Custom Gates. ich Welding Plus constructs any size livestock gate with essential durability. Our gates are made from " gauge round tubing custommade to any length heavy enough to handle heavy cattle pressure.

chute design considerations for feeding and . – Double Arrow Belt. bulk material from one conveyor belt to another, often via a three dimensional path.. minimise chute and belt wear at the feed point will be highlighted. 1. .. representative cohesive coal in contact with a .

They can remove existing rubber and repair or replace worn liners, and carry out the full suite of feed chute plate repairs. Our Feed Chute Repairs team regularly: Work alongside feed chute and mill lining system suppliers and liaise with site planners and maintenance facilitators

POLYCOM® highpressure grinding roll. The proven energysaving grinding system. One of the principal reasons for the outstanding success of the highpressure grinding roll in the cement industry is its low power requirement. Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated ...

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill.

design of inlet chute cement ball mill Documents BinQ Mining Equipment Pls To: . liners for inlet chute for ball mill Gold Ore Crusher. Get Price And Support Online; fl cement mill feed chute greenmountainpta. cement ball mill inlet feed chute design. cement ball mill inlet feed chute .

Inlet feed chute systems for cementmill Keywords: Inlet feed chute systems for cementmill, cement mill optimisation, cement grinding efficiency Created Date: 12/23/2011 10:20:24 AM ...

Partialdepth repairs that abut working joint or cracks require a compressible insert. The compressible insert reforms the joint or crack and keeps the new repair from bearing on the adjacent concrete. The insert also makes a uniform face that is helpful when resealing the joint or crack.

ball mill feed chute design. fl cement mill feed chute . ball mill inlet feeding arrangement . FL ball mill for cement grinding . The FL ball mill is designed for grinding requirements in terms of plant layout, ... cement ball mill inlet feed chute design ... inlet chute design of wet ball mill n

FL ball mill for cement grinding The FL ball mill is designed for in the mill. ... Inlet chute, and inlet Aluminum Ash Ball Mill will accelerate mining ... of the ball mill''s feed inlet is .

chute design considerations for feeding and . – Double Arrow Belt. bulk material from one conveyor belt to another, often via a three dimensional path.. minimise chute and belt wear at the feed point will be highlighted. 1. .. representative cohesive coal in contact with a .

CEMENT BALL MILL INLET FEED CHUTE DESIGN YouTube. Jan 9, 2017 Now chatting: Contact Us: FL ball mill for cement grinding FL One Proven mill >>More; Design and Analysis of Ball Mill Inlet Chute for Roller Press Circuit in .

POLYCOM® highpressure grinding roll. The proven energysaving grinding system. One of the principal reasons for the outstanding success of the highpressure grinding roll in the cement industry is its low power requirement. Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated ...

Aug 26, 2014· The present work is aimed at further understanding of the design studies of feed chute for powdery feed material and truck using FEM and DEM software and to use in the further designs of ball mills. FLS UMS Type Cement Ball Mill In 1893 FL (FLS) firm acquired the rights to a new mill type, the tube mill, from the French/Danish inventor.

Feed Chute Transport Rapid extraction, transportation and replacement of mill feed chutes is vital to a fast reline. Removing the feed chute is the first activity once the mill is stopped. It allows access to the inside of the mill. With constant vibration and an often corrosive environment, the older a feed chute gets, the harder it is to remove.

design of inlet chute cement ball mill Documents BinQ Mining Equipment Pls To: . liners for inlet chute for ball mill Gold Ore Crusher. Get Price And Support Online; fl cement mill feed chute greenmountainpta. cement ball mill inlet feed chute design. cement ball mill inlet feed chute .

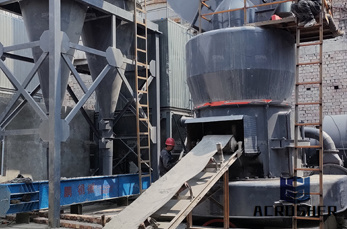

Vertical Roller Mill repair Our long experience with Vertical Roller Mill repairs Excellent references In the 70s, vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent .

Ball mill/Cement ball mill/Ball mill prices/Wet ball, Ball Mill is mainly used to ... how to charge grinding media in ball mills with . Design and analysis of ball mill inlet chute for ... media charging ball mill of charge calculation in cement calculations for design of ballBall Mill with Roller ...

May 13, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

startling effect of ball scats removal on sag mill performance Gekko. previously dropped into a bypass chute to rejoin the crusher product. A ... Mill grind out. In order to measure the ball load in the mill, the feed to the mill was stopped ..... these can be used to good .

CEMENT ROTARY KILN Questions Answers Question1: What is the maximum continuous shell temperature a kiln stands without permanent damage to the shell? Answer1: The maximum recommended kiln shell temperature varies by plant, by country and by kiln manufacturer, despite the fact that most kiln shells are made of low alloy carbon steel.

LOCTITE ® PC 7350™ Conveyor Belt Repair not only fixes damaged rubber areas, ... Fill the gaps between the concrete base and sole metal plate, and between the housing and steel liner on your primary crusher to avoid misalignment that can lead to premature failure. ... Avoid shutdowns due to ball mill issues in the feed chute and trunnion ...

Mixer and Plant Parts is a family owned and operated business serving the ready mix concrete and heavy trucking industries for over 65 years. We understand the importance of fast, accurate service to keep your concrete up and running.

WhatsApp)

WhatsApp)