second hand separation bentonite used machines YouTube

Jul 28, 2019· Onlin Service : This Channel Have Equipments Working Video : https://

WhatsApp)

WhatsApp)

Jul 28, 2019· Onlin Service : This Channel Have Equipments Working Video : https://

The blending method provides foundries with the ability to adjust and control additive requirements for the entire range of cast metal production to meet the expectations of the future. IMQUICK ® Water is THE essential component in the activation of bentonite used to bond in the green sand process.

The main uses of bentonite are for drilling mud, binder ( foundrysand bond, iron ore pelletizer), purifier, absorbent ( pet litter), and as a groundwater barrier. As of around 1990, almost half of the US production of bentonite was used for drilling mud.

LIST OF MAJOR CONSTRUCTION PLANTS EQUIPMENTS CODE NO. CODE DESCRIPTION EARTH MOVING EQUIPMENT: 0101 Dozer 0102 Wheel Loader 0103 Hydraulic Excavator 0104 Vibratory Compactor ... 0412 Bentonite Mixing and Generating Unit FLOATING EQUIPMENTS FOR MARINE WORKS: 0501 Jack up Platform 0502 Cutter Suction Dredger

Using Bentonite As A Wine Clarifier. By Ed Kraus. What is Bentonite? Bentonite is a gray, clay granule that is used in wines as a clarifier. It is unique in that it possess a negative electrostatic charge. (Just a fancy word for static electricity) This attracting charge along with hydrogen bonding, causes suspended particles in the wine to cling to it as it settles to the bottom of the container.

Bentonite is a kind of clay mineral with stable chemical property, it is also called the ''allpurpose stone''. The diffraction test shows that the particle size of bentonite is approaching nanometer scale, it can be proved that the bentonite is a kind of nature nanometer material.

what equipments are used in the production of . Wyoming is the nation''s leader in bentonite production with nearly 4 million tons of using scrappers and other heavy equipment once the topsoil is removed. Originally, Wyoming bentonite was used by local Indians as a bleaching clay and...

The bentonite grinding mill produced by Vanguard Machinery has increased the output of other production equipment by 10%. The whole process is closed, pollutionfree and meets national standards. It has provided a bentonite grinding production line fo

SOILMEC BENTONITE TURBO MIXER (BTM1000) Model: BTM 1000 Tank Capacity: 1000 litres Production Per Hour: 1012CuMts/Hr Power Rating: 11KW Description Designed for the efficient mixing and homogenizing of Bentonite with water which is used as the Drilling fluid.

Chapter 16, "Cutoff Walls," is an existing chapter within Design Standards No. 13 – Embankment Dams, and was revised to include the following changes and additions:

Grinding Mill. XSM grinding mills vary from coarse grinding, medium grinding to micro fine Mill(Grinder Mill)is widely used in metallurgy, building materials, chemicals, mining minerals in areas such as grinding materials materials include line, calcite, barite, coal, gypsum, mica and bentonite powder.

hydraulic crusher used in bentonite equipment Sierra Leone. Libya bentonite tretment production line low price for sale YouTube 14 Jan 2014 Libya bentonite tretment production line is a very common coarse quartz sand crusher it can be seen in most of the gravel . Get Price. live chat

Bentonite is a type of clay that has an ability to swell and gel when dispersed in water which is used in construction mainly in excavation and foundation works. The word Bentonite is a toponym taken from a place called Fort Benton in USA, where it was discovered as a clay ore. Bentonite is of a ...

the trench excavation equipment, desander or decanter and slurry handling pumps. A typical network for trench excavation is illustrated in the sketch below. Equipment for Trench excavation are of the following type. Reverse mud circulation rig are the first generation equipment used for Diaphragm wall trench excavation. They use a

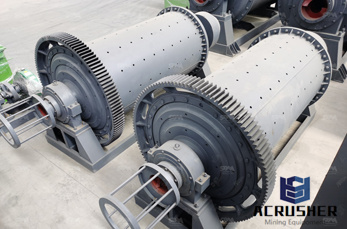

Bentonite Processing Machine. The Bentonite Processing Machine is a powerful milling machine that plays an important role in the milling line. At the same time, it is also the main industrial equipment in the building. The requirements for the use of milling equipment are different in different fields.

are used for refractories or to raise vitrification temperatures in heavy clay products. Bentonite is a clay composed primarily of smectite minerals, usually montmorillonite, and is used largely in drilling muds, in foundry sands, and in pelletizing taconite iron ores. Fuller''s earth is defined as a nonplastic

Jul 08, 2014· Cornsoya based mash diet has problem in flowing in the feeder and it gets stuck in the bridge. Some of the literature say that sodium bentonite can be mixed at the rate of 2kg/ton to overcome this problem. I need practical suggestion regarding use of sodium bentonite in poultry mash feed.

Iron ore pellets are spheres of typically 6–16 mm (– in) to be used as raw material for blast typically contain 64%72% Fe and various additional material adjusting the chemical composition and the metallurgic properties of the pellets. Typically limestone, dolomite and olivine is added and Bentonite is used as binder.. The process of pelletizing combines mixing of ...

may range from (6 gal./sack) to (7 gal,/sack). Bentonite is commonly used as an additive (12%) with these types of cement. The amount of water necessary to hydrate the slurry properly increases with addition of bentonite. Bentonite Sodium bentonite is the principle ingredient in drilling mud or fluid used in rotary drilling.

Technical Info Industrial Lubricant Recovery And Purification The clays used in our oil purification process (such as Fuller''s Earth) are bentonite clays. When properly pretreated (or "activated"), the clay will attract impurities, which become chemically attached to the clay, removing them from the oil. ....All our equipment is drained and flushed between jobs to avoid cross ...

Aug 20, 2013· THE PRODUCTION TECHNIQUE OF BENTONITE PROCESSING. This method improve the quality and efficiency of activated clay, decolorizing capacity by increasing the activation temperature and pressure with a small amount of water washing slurry material, which greatly reduces the cost of production. THE FIRST STEP:

SLURRY WALL RETAINING SYSTEMS FOR DEEP EXCAVATIONS. Diaphragm Walls ( Slurry Walls) The continuous diaphragm wall (also referred to as slurry wall in the US) is a structure formed and cast in a slurry trench (Xanthakos, 1994).

Slurry walls are constructed using a bentonite or cementbentonite slurry to stabilize the trench during excavation. Whether cutoff or structural walls, Hayward Baker can provide the optimal design and/or construct solution for your belowgrade wall need.

offers 3,810 machine bentonite products. About 4% of these are bentonite, 1% are adsorbent, and 1% are other nonmetallic minerals products. A wide variety of machine bentonite options are available to you, such as free samples, paid samples.

WhatsApp)

WhatsApp)